Kaidi DTBZ series explosion-proof solenoid is a hydraulic solenoid product which is specially designed for mining industry with flameproof Exd I Mb environment and chemical industry with flameproof Exd II CT4 environment. Kaidi Explosion proof solenoid has been widely applied in the control components with explosion proof requirements, such as the directional control valves of hydraulic systems in the environment with explosive gases like coal dust, methane, etc. In another word, the explosion-proof solenoid is designed for the equipment used in mining industry, chemical industry, and petroleum industry.

Explosion Proof Solenoid Working Conditions

- Explosion proof solenoid must be used in the environment with atmospheric pressure between 80 – 110kPa;

- Explosion proof solenoid must be used in the environment with temperature between -20℃ – 40℃;

- Explosion proof solenoid must be used in the environment with relative air humidity no more than 95% (when the air temperature is 25℃);

- Explosion proof solenoid should be used in coal mine shaft with explosive gases such as methane, coal dust, etc.

- In order to make the hydraulic valve work stably, the hydraulic oil must maintain the following features: viscosity between 10 – 350cst, filter fineness no more than 25u.

Explosion Proof Solenoid Structures

The most popular explosion proof solenoid is DC wet type explosion proof solenoid. AC explosion proof solenoid is a structural form of the inbuilt electronic rectifying device of DC wet type structures. Explosion proof solenoid connects with the hydraulic directional valves with the threaded connection on the end of hydraulic solenoid tube, which make the explosion-proof solenoid and hydraulic valve a complete unit.

When the hydraulic solenoid has been electrified, the solenoid coil creates a magnetic field, which can magnetize the magnetic materials on hydraulic explosion proof solenoid, and drive the solenoid armature moves towards the pole face of the stop iron. The movement of solenoid armature will drive the displacement of solenoid plunger, therefore, it can push the spool of hydraulic valve to move under its requirements. There is no reset element for hydraulic solenoid when the power has been cut off, the solenoid armature will reset by the counter force of the spring inside hydraulic valve. Explosion proof solenoid has been widely applied to many different types of equipment with it characteristics such as small size, lightweight, and easy installation, etc.

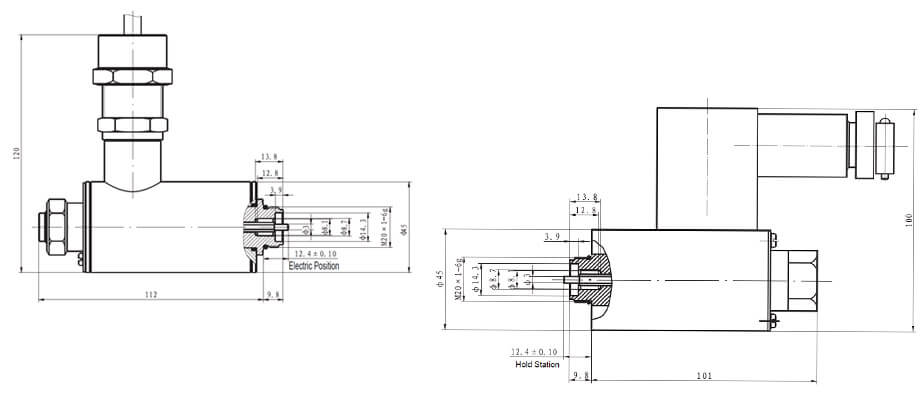

Explosion proof solenoid structural diagram

Explosion Proof Solenoid Structural Features

- In order to be explosion proof, when the explosive mixtures explode in the cavity of explosion proof solenoid, the outer case of explosion proof solenoid will not be damaged. And at the same time, the internal flame must not cause the explosive mixtures outside the explosion-proof solenoid explode through the joint face of the explosion-proof solenoid outer case.

- All the components that used to make the explosion-proof outer case have gone through the precise manufacturing process, and have been tested to make sure it can sustain the biggest internal explosion pressure and not be damaged.

- The numbers of fastening bolts that used to connect the explosion-proof outer case cannot be less. In order to sustain the explosion pressure, the screw depth must between 1.2 – 1.5 times of the diameter of the bolt. And under each bolt and nut, there must be a spring washer to prevent the bolts from loosening.

- The outer case, junction box cover, base plate, solenoid tube and cable seals of explosion proof solenoids are the actual explosion proof elements, so it cannot be bumped. And there should not be scratches on the surface of explosion proof elements to ensure the explosion-proof effects.

- There are seal rings on both the inlet and outlet of the junction box. The minimum outer diameter of cables is the same with the inner diameter of the seal rings. Therefore, it has no clearance between seal rings and cables, and between seal rings and junction box. Otherwise, it can not explosion proofed.

Explosion Proof Solenoid Installation

Before you installed the explosion-proof solenoid, there must be a series of experiments that have been taken. If any of the experiment is not qualified, the utilization of the explosion-proof solenoid is not allowed.

- Make sure the solenoid has safety mark and the serial number of the safety mark.

- Make sure the solenoid has the explosion-proof sign and the conformity certificate of explosion-proof.

- Make sure all the fasteners have been screwed down, and all the spring washers are in place, all the parts of the explosion-proof case have been connected properly.

- Make sure there is no scratch and crack or other flaws that can reduce the explosion-proof performance on the explosion-proof elements of explosion proof solenoids.

Kaidi Electromagnetic is a leading hydraulic solenoid manufacturer in China, which is specialized in manufacturing all types of hydraulic solenoids for hydraulic valves. If you have any types of requirements of hydraulic solenoid, please feel free to contact us, Kaidi provides fully customized hydraulic solenoid solutions for global valve manufacturers.