Hydraulic solenoid is the actuator of hydraulic valves, different hydraulic valves use different hydraulic solenoids, such as on-off solenoid for directional control valves, proportional solenoid for hydraulic proportional valves, etc.

During the operation of hydraulic solenoid valve, hydraulic solenoid is the easiest damaged part of the complete hydraulic valve assembly. And among all different hydraulic solenoid damages, the most common problem is hydraulic solenoid burn out. Therefore, in the following article, we will focus on the hydraulic solenoid burn out problem.

What Cause Hydraulic Solenoid Burn Out?

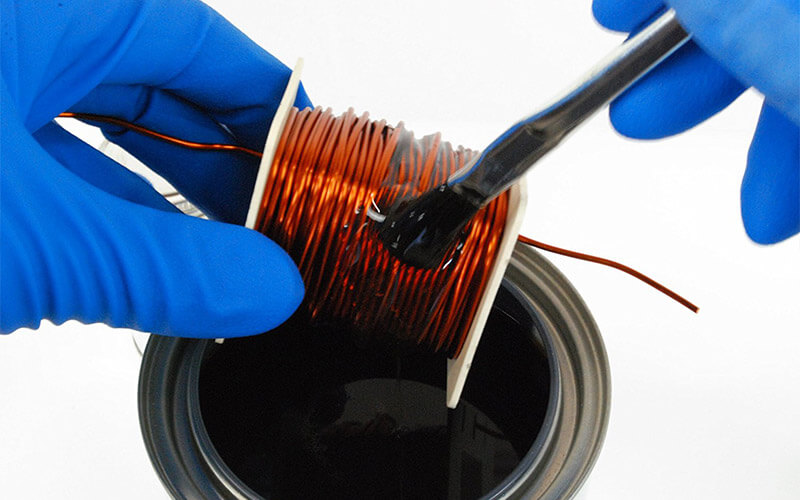

Hydraulic solenoid burn out problem normally caused by the solenoid coil damage. Hydraulic solenoid coil is multiple wraps of copper wires, the solenoid coils used for on-off solenoid and proportional solenoid are the same.if the copper wires burn out, the complete hydraulic solenoid assembly will burn out.

Below are some situations that can cause solenoid coil burn out.

The Insulating Varnish of Solenoid Coil

The copper wires of hydraulic solenoid coil must use the specified grade insulating varnish, if not, the solenoid coils may burn out because of defective insulation.

During the working process of hydraulic solenoids, the insulating varnish of solenoid coil copper wires may be damaged for different reasons. Maybe the insulating varnish may be peeled off, maybe the insulating varnish damaged by strong impact, or the solenoid terminals may suffer the aging problem of the plastic wrapping of wires, which can cause electricity leakage and short circuit problems. Moreover, the solenoid coil burn out problem may also be caused by bad quality control during hydraulic solenoid manufacturing process. In that way, the bad quality hydraulic solenoid must be replaced, or we should re-wiring the solenoid coil.

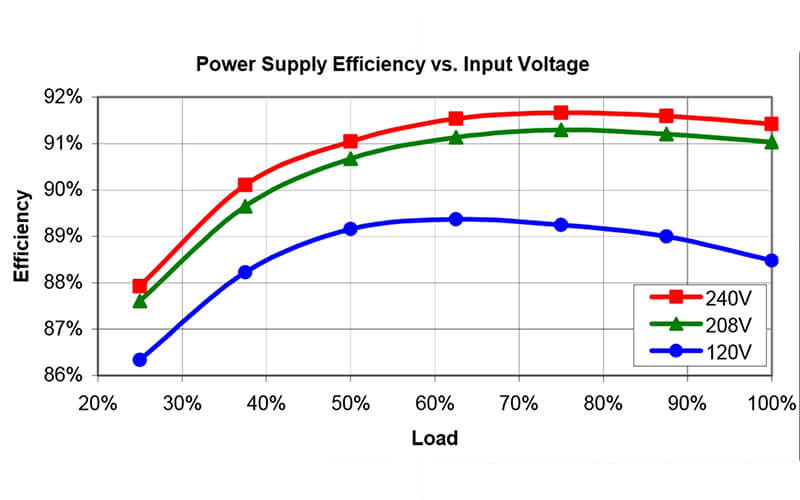

Hydraulic Solenoid Voltage

If the voltage is too high or too low can also cause hydraulic solenoid burn out. When the hydraulic solenoid voltage is too low, the force of hydraulic solenoids drops, which makes it cannot overcome the loading resistance (such as the replacement force of spring, the valve resistance, and fluid force, etc), in that way, the hydraulic solenoid will burn out by the overload heating problem. When the hydraulic solenoid voltage is too high, the force of hydraulic solenoids is too large, which makes the solenoid iron core easy to close. The over high voltage creates overlarge holding current, the current will make the solenoid coil keep overheat, and finally, the hydraulic solenoid burns out. Generally speaking, the minimum voltage of hydraulic solenoid is no less than 80% of the rated voltage. Take 220v hydraulic solenoid as an example, the minimum voltage of 220v solenoids cannot be lower than 180V.

Hydraulic Solenoid Power System

If we select a wrong power system for the hydraulic solenoid, it can also cause the burn out problem of solenoid coil. Such as the mix of dc voltage and ac voltage, the needed voltage is over the allowable voltage range, etc. Some factories have their own power generating system, and the voltage is not so stable, but in order to prevent the hydraulic solenoid from burning out, the circuit better has stable power source.

External Environment Factors

The overheat external environment can also cause the burn out problem of solenoid coils. There are many ways will create an overheat external environment for hydraulic solenoids, such as the direct sunlight, the hydraulic oil temperature is too high, the indoor temperature is too high, poor result of ventilation and heat-dissipation, etc. All these causes can make the solenoid coil aging earlier.

Despite the temperature problem, when the vapor, conducting dust, corrosive gas and other gases that can damage the insulation in the air enters the hydraulic solenoids, will surely cause the solenoid coil dampened and rust. So if the hydraulic solenoid must work in the high moisture environment, we highly recommend the hydraulic solenoid specially designed for high moisture environment.

Improper Operation of Hydraulic Solenoid

If the direction changing frequency of hydraulic solenoid is too fast, then the accumulation of heat is much faster than the dispersion of heat. In that way, the hydraulic solenoid will lose its force quickly. If the force of hydraulic solenoid is not enough, then it can not be fully closed. If the direction changing frequency of hydraulic solenoid is continuously over speed, the high frequent actuating operation will create enough electricity that can burn out hydraulic solenoids.

Hydraulic oil can also effect hydraulic solenoid operation. If we use the hydraulic oil with high viscosity, high viscosity creates large resistance, if the resistance is over the loading range of hydraulic solenoid, the solenoid coil will burn out because of the overload problem.

Hydraulic Solenoid & Valve Design Flaws

Hydraulic solenoid is used on hydraulic valve, so if there is design flaws on the hydraulic solenoid and valves, the solenoid coil will be damaged.

For example, the oil hydraulic circuit design, the processing precision of hydraulic solenoid valves, the rigidity of the replacement spring, any of these factors is designed without precise calculation, it can cause the solenoid coil burn out.