The role of hydraulic system is aimed to enhance the force through the change of pressure. A complete hydraulic system is consist of five parts: power element, conducting element, control element, auxiliary element and hydraulic oil. Typically, there are two types of hydraulic systems, hydraulic transmission system, and hydraulic control system. The main function of hydraulic transmission system is to transmit power and movement. And the function of hydraulic control system is to make sure the output of hydraulic system has reached the specific performance requirements (especially the dynamic performance).

Hydraulic System Components

Hydraulic systems consist of five different components: the power elements, conducting element, control element, auxiliary element and hydraulic oil. In the following articles, we will discuss the what are the hydraulic system components.

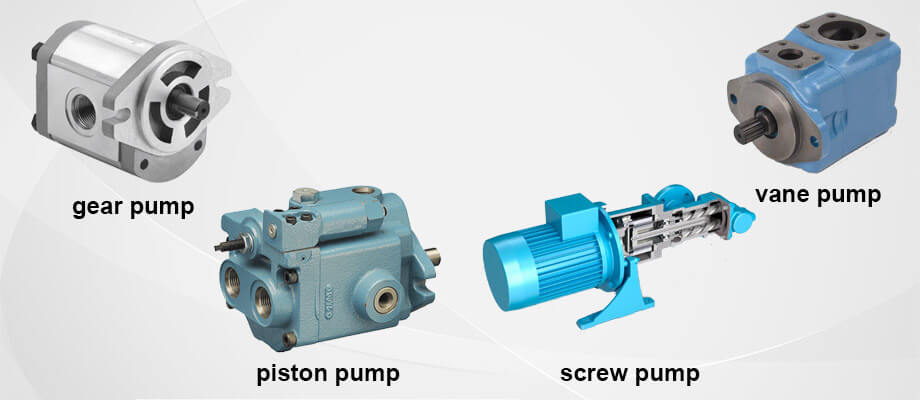

Hydraulic System Power Component

Hydraulic system power components are used to convert the kinetic energy of the prime movers into pressure energy of the fluid. The typical hydraulic system power component is the hydraulic oil pump of hydraulic systems, which provides power for the complete hydraulic systems. There are different types of hydraulic pumps for different hydraulic systems, such as gear pumps, vane pumps, piston pumps, and screw pumps.

Hydraulic System Conducting Component

Hydraulic system conducting component is used to convert the pressure energy of fluid oil into kinetic energy to do a linear movement or rotary movements, such as hydraulic cylinder, and hydraulic motor.

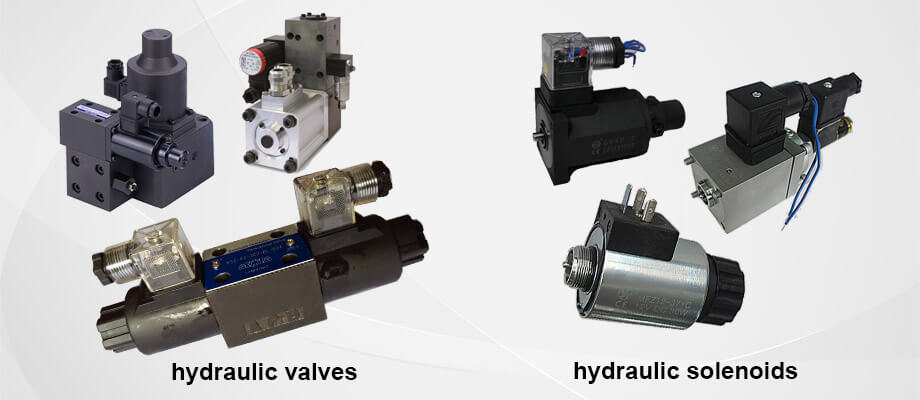

Hydraulic System Control Component

Hydraulic system control component refers to many different types of hydraulic valves used to control and adjust the pressure, flow, and direction of the fluid. According to their different control functions, hydraulic valves can be divided into three types, hydraulic pressure control valves, hydraulic flow control valves, and hydraulic directional control valves. Moreover, hydraulic pressure control valves can be divided into hydraulic relief valves (aka hydraulic overflow valves), hydraulic pressure reducing valves, pressure relay, etc. Hydraulic flow control valves include hydraulic throttle valves, hydraulic adjustment valves, hydraulic flow distributing and collecting valves, etc. And hydraulic directional control valves also include several different types of hydraulic valves, such as hydraulic check valves, hydraulic shuttle valves, hydraulic directional valves, etc.

In addition, based on different control methods, hydraulic valves can be divided into three types, hydraulic on-off valves, hydraulic proportional valves, and set point valves.

Hydraulic valves can be actuated by different devices. Take hydraulic directional valves as an example, there are manual directional valves which connect with a hand lever, and you must manually shift the directions and electro directional valves which connect with a hydraulic solenoid that can be actuated automatically. But for different types of hydraulic proportional valves, proportional solenoid is the common power element for them, as it requires precise control system.

Hydraulic System Auxiliary Component

The auxiliary components of hydraulic system include: hydraulic oil box, hydraulic oil filter, cooler, heater, accumulator, oil pipe and joint, seal ring, quick release coupling, high-pressure ball valve, hose, pressure gauge, oil level indicator, oil temperature indicator, etc.

Hydraulic Oil

Hydraulic oil is the working media which transmit energy in the hydraulic systems, such as all types of mineral oils, emulsion, and synthetic hydraulic oils.

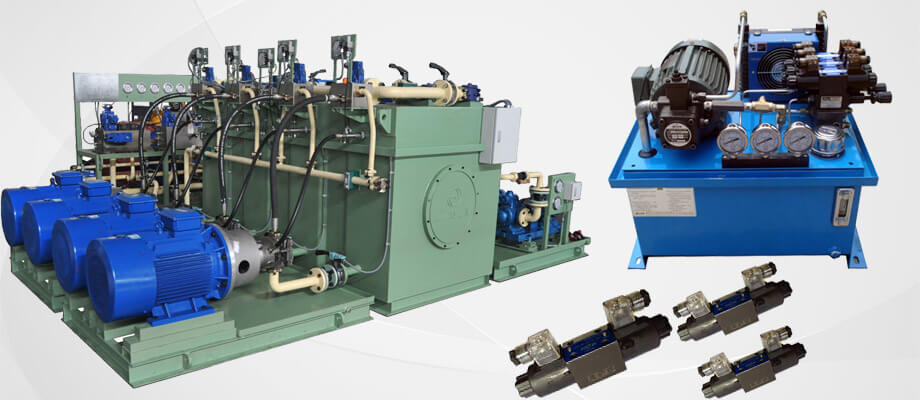

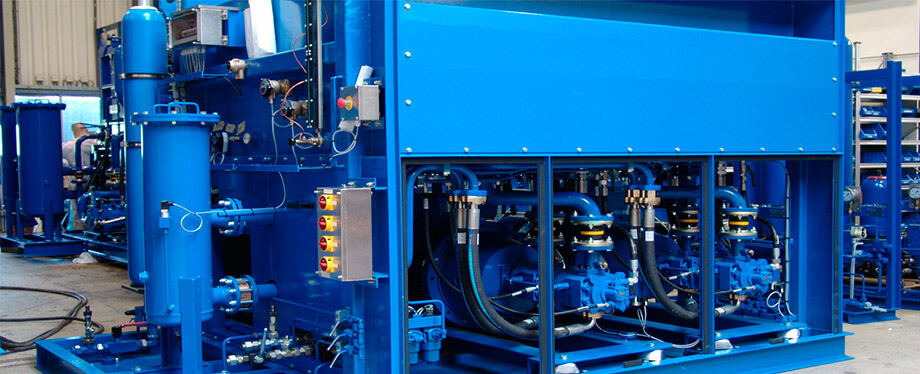

The Structure of Hydraulic Systems

Hydraulic system is consist of two parts, signal control unit and hydraulic power unit. The signal control unit used to drive the movement of the hydraulic control valve in hydraulic power unit.

About hydraulic power unit, the hydraulic pump, electromotor, and auxiliary components are the hydraulic sources. About hydraulic control unit, there are all types of hydraulic valves to control the flow, pressure, and directions of hydraulic oils. About hydraulic operative unit, there are hydraulic cylinder or hydraulic motor that can be chosen by different requirements.

Hydraulic System Pros & Cons

Hydraulic system and pneumatic system are the most common systems for machine manufacturing. It is a shared understanding that hydraulic systems are more popular than pneumatic systems. One of the major reason is that a hydraulic system can produce much more force than a pneumatic system with the same size, therefore, the energy cost by using hydraulic systems is much cheaper than the energy cost by using pneumatic systems. But is hydraulic system superior in every way than pneumatic system?

The Advantages of Hydraulic Systems

Hydraulic systems have small volume and light weight can be used on many different machines.

Hydraulic systems maintain great stiffness, high accuracy and short response time.

Hydraulic systems have large driving force, which is suitable for heavy load direct drive.

Hydraulic systems adopt large speed regulation range, which provides multiple speed control types.

Hydraulic systems have self-lubricating function and self-cooling function, which makes hydraulic systems have longer service life.

Hydraulic systems show easy safety protection system.

The Disadvantage of Hydraulic Systems

Hydraulic systems show poor pollution resistance performance of hydraulic oil.

Hydraulic systems are more sensitive to temperature variation.

Hydraulic systems need hydraulic energy source, such as hydraulic oil.